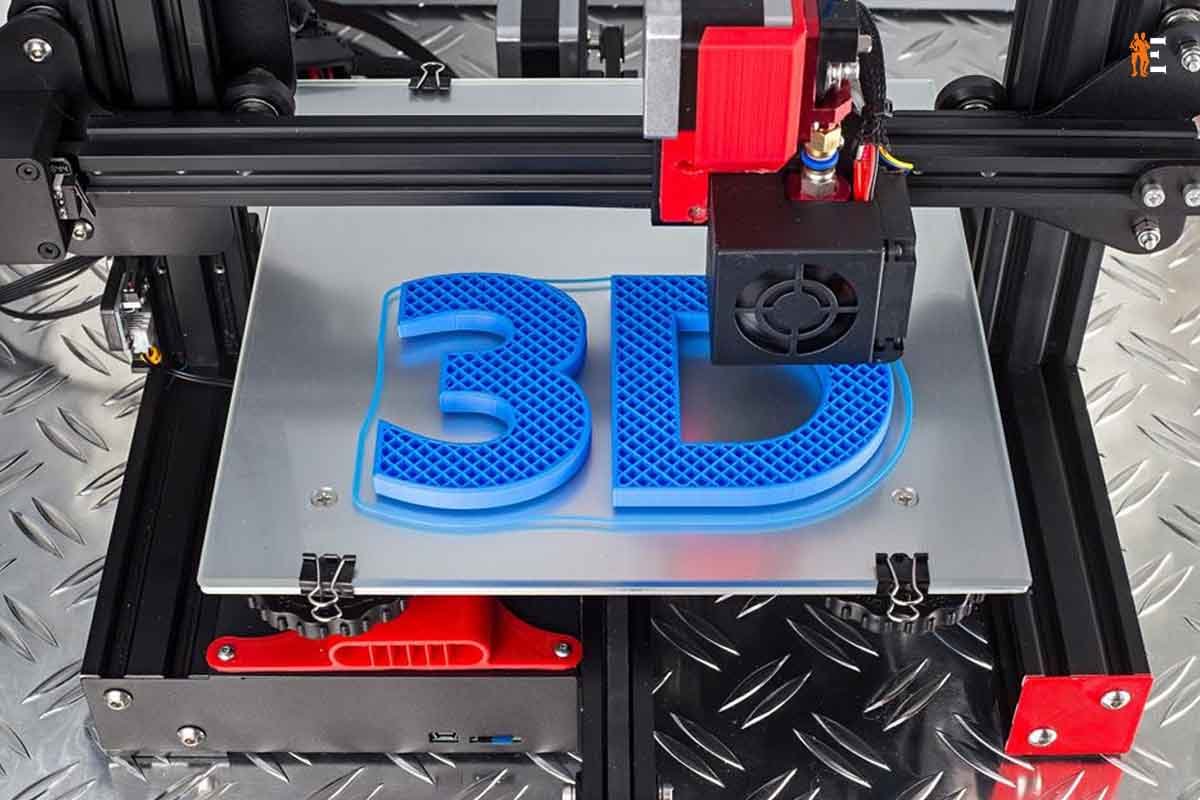

In 3D printing, a real item is created from a digital model by successively adding tiny layers of filament (often plastic). The printer receives a digital file that serves as the basis for the model. The 3D printer builds out an item by successively adding tiny layers. Compared to conventional manufacturing methods, Guide for 3D Printing also permits the creation of objects with more complicated designs while using far less material.

According to historical records, the advent of 3D printing occurred in the 1970s. In fact, it wasn’t until 1980 that the first tools and materials for additive manufacturing were created. Hideo Kodama began the patenting process for this innovation but never took it to market. There was a surge of interest in 3D printing from researchers and developers of cutting-edge technology in the 1990s. At the same time period, completely functioning human organs were developed for transplant in young children utilizing Guide for 3D Printing techniques covered with particles and cells from the patient’s own body. It was a huge win for the healthcare sector.

In spite of these developments, the functional Guide for 3D Printing output was low until the advent of additive manufacturing in the 2000s. While using additive manufacturing, materials are added together until a finished product is achieved. Compared with the idea of subtractive manufacturing, the process of additive manufacturing is quite different. In subtractive manufacturing, an item is created by cutting away excess material from a flat surface. There is a lot of waste product in this process as well. In this context, the terms 3D printing and additive manufacturing often refer to processes that use polymer materials and metalworking, respectively. The market, media, businesses, and producers all started using the words for these two processes in the early 2010s.

Later years saw the development of further Guide for 3D Printing uses, including the first-ever airplane. As opposed to more conventional manufacturing techniques, 3D printing speeds up the prototype process and reduces costs, according to those who use it (RP). Since then, 3D printing has been associated with desktop manufacturing, quick manufacturing, and rapid prototyping.

There is a vast range of Guides to 3D Printing available today. Although more complex machines might break the bank, cheaper alternatives can provide impressive print quality and functionality. Desktop printers that are suitable for 3D printing are also becoming more common in classrooms and laboratories.

Here are 3 Answers in a Beginner’s Guide for 3D Printing;

1. How Does 3d Printing Work?

To sum up, 3D printing involves combining successive layers of material to create a final product. The computer 3D modeling software directs the 3D printer’s actions here, ensuring their precision and accuracy.

While there are many different kinds of manufacturing methods that fall under the umbrella of “3D printing,” they all accomplish the same goal—the creation of models—by building them up in successive layers. Each of these Guide for 3D Printing production techniques may call for a unique material, end result, and financial investment.

FDM, SLS, SLM, SLA, and DLP are examples of widely used and popular technologies. Below is a synopsis of each of these developments for your perusal.

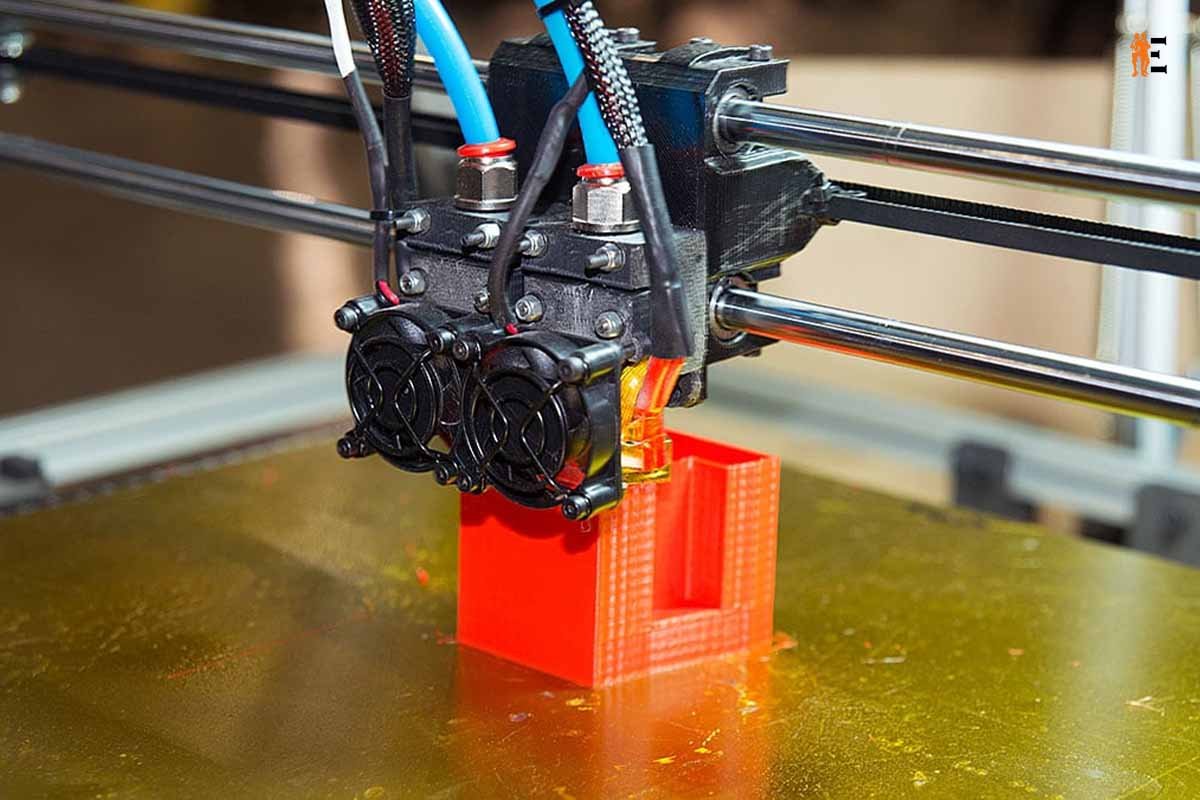

First, we’ll talk about Fused Deposition Modeling, or FDM, which is a brand name provided by Stratasys and happens to be the most popular of them. While this idea dates back to the 1990s, it has only been since 2009 that many 3D printers have begun to use this method. Moreover, this is known as FFF technology (Fuse Filament Fabrication). By the use of a heated extruder, plastic is melted and placed in successive layers until the desired shape is achieved. ABS and PLA filaments are the most popular options for 3D printing.

- Guide for 3D Printing

- Creation of objects

- Fused Deposition Modeling

Selective Laser Sintering (SLS) is another additive manufacturing technique that employs a laser to fuse powdered plastic into a three-dimensional solid. Prototyping and low-volume production go smoothly and quickly with this technology, so it’s often a top pick.

Powdered metals may be melted and fused together via SLM, or selective laser melting, thanks to the employment of a powerful laser. This method allows for the complete melting of the metal substance into a solid Guide for 3D Printing sculpture. Parts that would be difficult or impossible to cast using more traditional techniques may be made with this technology since the form can be built up layer by layer. A computer-aided design (CAD) program slices the file into layers; the STL file is then imported into file preparation software; and finally, a high-powered laser beam melts the material until the component is complete.

High-detail, flawlessly finished, and well-made components are the result of persistent SLA or stereolithography. As you would expect, this technique finds widespread usage in the mechanical sector and in the realm of models.

Last but not least, Digital Light Processing (DLP) is a method similar to SLA in which light is used to cure the resin ingredients using a light projector screen. As a complete layer can be constructed at once thanks to the utilization of light, this method is quicker than others, albeit it is best suited for low-volume manufacturing runs of primarily plastic products to Guide for 3D Printing.

2. How 3D Printing Works?

1. Make a CAD (Computer-Aided Design) file

An electronic model, made using software or a Guide for 3D Printing scanner, is the initial stage in the 3D printing process. Using this, you may preview the final product of your 3D printing project by entering in the precise measurements of the thing you want to make. Errors are less likely to occur during the printing process if they are not introduced during the design phase of a 3D item using CAD, and thankfully, they may be fixed in advance. Manual creation methods like sculpting also need a 3D scanner to capture the data, form, and look of the final product.

2. Change the CAD file type

When a design has been drafted, it must be exported in a format that can be read by the Guide for 3D Printing. STL is a popular file format (standard tessellation language). Sometimes the number of surfaces in an STL file can cause the file size to increase. Another alternative is the Additive Manufacturing File Format (AMF), which is used to store data in a more manageable manner.

3. Modify the STL file

Setting the object’s orientation and size in the STL file is the last step before sending it to a 3D printer. We can also fix any irregularities in the original model thanks to STL files.

4. Get the 3D printer ready.

Everything needed to begin printing must be prepared before the digital file can be sent to the printer. After the STL file is complete, it will need to be processed by slicing software, which breaks down the item into layers and generates the instructions that will be sent to the Guide for 3D Printing.

5. Construct the item

The printing procedure may commence after all the aforementioned conditions have been satisfied. Depending on the complexity of the item being printed, certain printers may need more time to complete the final result. Nowadays, you can find many of printers that both print quickly and offer advanced features. As soon as the process starts, the layers begin to construct the item with an unprecedented level of detail, as measured in a unique unit of micrometers. As an example, a normal layer is just approximately 100 micrometers thick.

6. Handle the finished product

When the item is prepared, it must be handled with extreme care. For instance, gloves should be used while handling the printed object, and any excess powder should be brushed off before the item is cleaned. Unlike more time-consuming and labor-intensive methods of production, Guide for 3D Printing allows for the creation of a finished product in a matter of hours.

In what way does an FFF 3D printer function?

Fused Deposition Modeling (FDM) is a trademarked name for Fused Filament Fabrication (FFF) (FDM). This innovation followed the development of SLA (Stereolithography) and SLS (Selective Laser Sintering). Due to the fact that “FDM” is a registered trademark, “FFF” was first used as a loose synonym Guide for 3D Printing.

The first step in 3D printing is the depositing of thermoplastic material onto a print bed in the form of thin layers, one on top of the other, until the final object is formed. This is accomplished by moving an extrusion heated nozzle over a built platform while simultaneously releasing molten plastic. When the plastic is being extruded, the nozzle and the printed bed shift positions. Important to the process is the slicing program, which slices the design into individual layers for Guide for 3D Printing.

Pastes, raw materials, and thermoplastics, often known as filaments, are some of the most commonly used materials in Guide for 3D Printing; they can be found in a broad variety of colors and thicknesses and are easily manipulated to get the desired effect. Thermoplastics, ABS, PLA, HIPS, TPU, ASA, PETG, PLA, etc. are all examples of filament materials used for extrusion.

3. What Can Be Printed in 3D?

The production of models and prototypes in business has been completely transformed by 3D printing. Rapid prototyping (RP) is a process through which a product may be created in a matter of hours or days as opposed to the weeks required by more conventional approaches. Almost everything you can imagine can be created with a Guide for 3D Printing.

Statista predicts that by 2024, the global market for Guide for 3D Printing goods and services would be worth more than $40 billion. According to this study, the IT services market would rise by 26.4% year between 2020 and 2024.

The potential uses for 3D printing are many. New materials and uses are being found every day, and as a result, more businesses are turning to this strategy for faster development and manufacturing of things, despite the fact that they already own printers.

Almost every sector of the economy stands to benefit from Guide for 3D Printing since technology is already being used by a wide range of major industrial organizations in product creation, research, education, and more.

Conclusion

3D Printing is helping many industries such as Automotive, Aerospace, Dental, Architectural, and more run efficiently. However, as a beginner exploring the world of 3D Printing, the first step is understanding its basics and slowly moving forward to implement 3D Printing optimally for your specific use case. As you move forward, we hope A Beginner’s Guide to 3D Printing above was helpful to you.